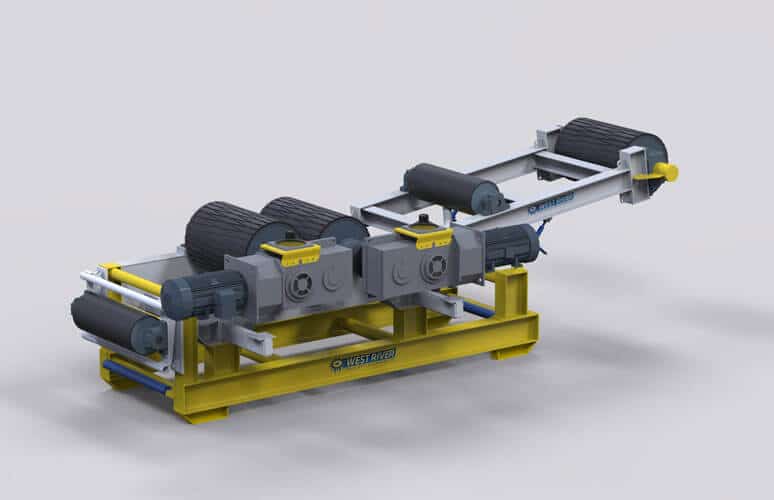

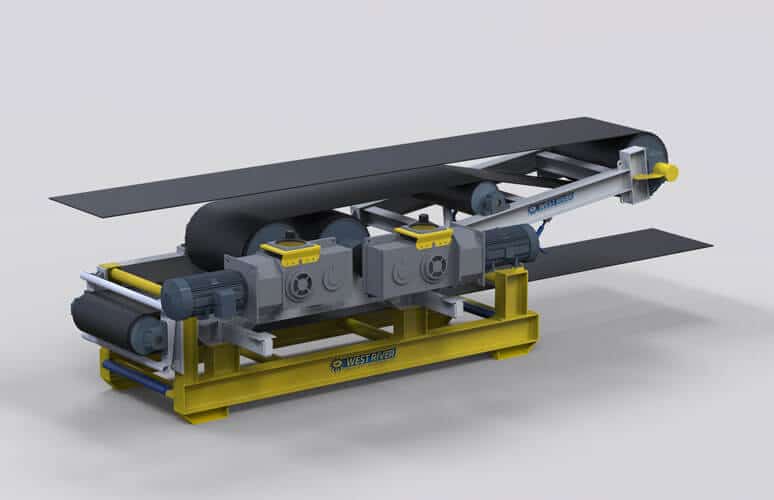

Drives are constructed from carefully selected, industry-leading materials to provide a strong and rigid, mine-duty frame that doesn’t distort during installation or use. West River’s heavy-duty frames are built from a heavier steel than many competitors use, providing a drive that withstands the most demanding underground and above-ground bulk material handling operations. Belt drives from West River come in a variety of sizes, belt widths, and horsepower required. West River’s ability to work with the customer to create a drive system suitable to their needs is the number one priority. Utilizing the most advanced design program available allows West River engineers the flexibility to create drives for unique applications.

Check out our lineup of Conveyor Belt Drives:

Alignment Free Drives

Chain Driven Drives

Combination Belt Drives

Shaft Mount Reducer Belt Drives

Cost-effective solutions for hauling aggregates like sand and gravel over long distances.

LEARN MORE

Improve mining operations with custom conveyors that are tested for safety and reliability.

LEARN MORE

An online inventory stocked with gearboxes, fluid couplings and other parts ready to be shipped.

LEARN MORE

Avoid unplanned downtime and injuries that can arise from worn out conveyor belts.

LEARN MOREProject and plant managers in the mining industry face the ongoing challenge of keeping conveyor belts clean. Dust and rocks can cause many problems, including worker injuries, compliance issues, and read more »

Conveyor systems and short-haul truck fleets remain the most popular and effective ways to move large amounts of bulk materials at many mining, construction, and processing operations. In this article, read more »

Adhering to complex OSHA mining conveyor safety regulations can be an ongoing challenge. There are many moving parts and areas where accidents could occur. However, failure to comply poses serious read more »