At West River, we understand that efficiency, price, and equipment durability are your leading concerns when purchasing conveyor equipment. We are committed to building quality products by listening to and understanding our customers’ needs.

West River builds durable, custom conveyor systems for the mining industry. Our conveyors are engineered to efficiently and safely transport copper, coal, salt, potash, and precious metal ores.

Our rugged conveyors withstand the mining industry’s challenges.

We build our custom conveyor systems tough and can provide a complete turnkey conveyor package or individual conveyor system components and parts.

Our custom conveyor systems include:

Learn More About Our Conveyor Systems

Underground mining conveyor systems must be high-quality due to the combination of dust, dirt, and confined spaces. These systems are also subject to various complex OSHA, MSHA, and state regulations.

We offer a variety of conveyor structures and belt options to meet your underground mining needs, such as conveyor structures, belts, terminal equipment, and accessories.

Every underground application is different—ask us about custom equipment packages tailored to your needs.

Move massive quantities of bulk materials from their source to stockpiles or processing facilities with overland conveyors, and keep operational costs and disruptions to a minimum.

Our customizable used and rebuilt conveyors are a prime option for managing your mining equipment needs. They offer many benefits our customers have come to appreciate, such as cost savings and customization.

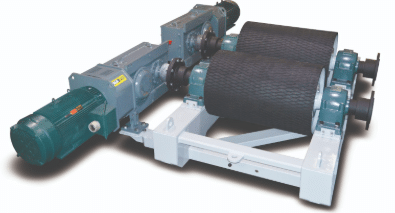

In addition to manufacturing our products, such as custom conveyor belt drives, we carry a wide assortment of terminal equipment from industry-leading brands. We can provide you with new, used, and rebuilt components and build whatever you need to your specifications.

Our terminal equipment includes:

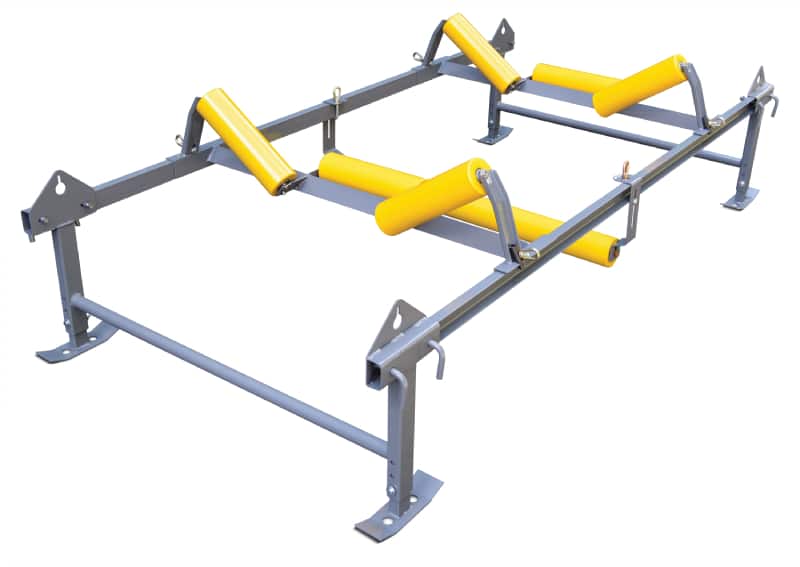

West River’s structure comes in CEMA B, C, D, E, and E+ and can be used for longwall and room-and-pillar operations. If conveyor specifications are provided, we can provide engineered idlers upon request.

Our custom conveyor structure includes:

Abrasive materials, heavy loads, and environmental factors can all contribute to conveyor belt failure. West River Conveyors offers underground and surface mining conveyor belts that can withstand the rigors and prevent unplanned downtime.

Our custom belts include:

Our certified engineers use cutting-edge technology to design and manufacture all our conveyor products on-site. We exercise strict quality control measures to ensure complete customer satisfaction with every product that leaves our facility.

We streamline our job processes to increase productivity and build your conveyor components promptly. Our investment in a PCR42 Structural Steel Plasma Cutting Robot enables more precise cutting and drilling.

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution.”

– William A. Foster, Medal of Honor Recipient

Learn More About Our Quality Control Measures

At West River, we have over 40 years of experience building custom conveyor systems for the mining and aggregate industries. We realize that each application is unique, and we can provide you with specialized or custom parts from major manufacturers to keep your conveyor equipment running.

West River Conveyors will design, build, and install your application’s customized dirt conveyor system. With over 40 years of experience, our expert engineers will help solve your toughest material-moving challenges. Our superior conveyor belt solutions enhance the safety and efficiency of your mining operations. Contact West River Conveyors today to discuss your requirements and discover how our products can contribute to your operational success.

Contact us online or at 800-322-2781 for more information and custom pricing!

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »

At West River Conveyors, we believe in being upfront with our customers, especially when changes in the global economy may impact your business. As a family-owned company proudly manufacturing conveyor read more »

A reliable conveyor system is essential for efficient mining operations. However, even the most well-maintained conveyor systems degrade over time, leading to inefficiencies, downtime, and higher operational costs. Knowing when read more »