For over 45 years, we have been a trusted leader in the material handling conveyor industry, providing top-tier steel fabrication solutions. Now, with significant investments in cutting-edge equipment, we’re proud to expand our capabilities and offer a wider range of custom steel fabrication services. Whether you need specialized components or have a large-scale project, our experienced team of AWS-certified welders is equipped to deliver precision and quality beyond conveyor systems.

Our large manufacturing facility enables us to handle large-scale steel fabrication projects of all shapes and sizes. With decades of experience building conveyor systems, we design and fabricate structural steel for the toughest conditions—whether underground, surface, in high humidity, dusty, corrosive, or extreme temperature environments. No challenge is too demanding.

Using design software and advanced cutting technology for precision, our team expertly manages the complexities of fabricating large steel structures, including tight tolerances, heavy component positioning, and minimizing welding distortion. Our skilled welders specialize in low, medium, and high-carbon steel, as well as aluminum when required.

Get a Quote for Steel Fabrication Work

To improve the quality of our fabrication work and the speed at which we get it done, West River Conveyors recently made some significant investments in manufacturing technology. New and enhanced capabilities include:

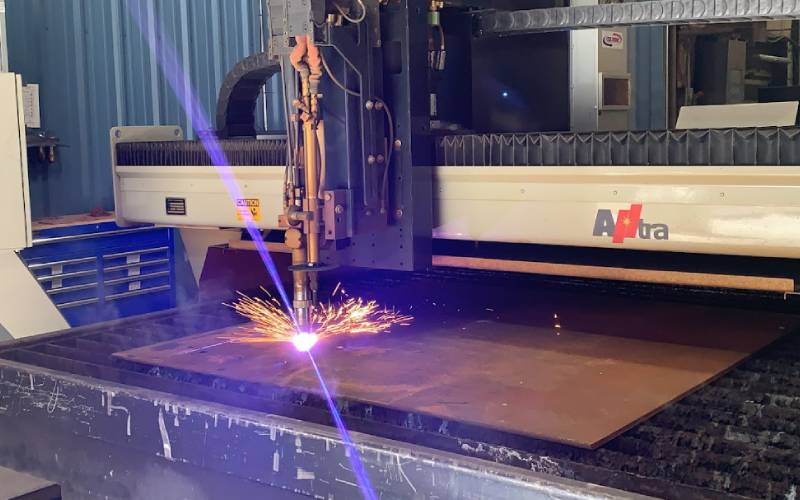

PG-14 Series CNC gantry plasma cutting machine – Equipped with a 275A Spirit IIA torch, this cuts thick steel plates up to 14’ wide quickly and accurately.

PCR42 plasma cutting robot – This state-of-the-art machine downloads CAD files from Solidworks and uses machine vision and robotics to cut beams, tubes, and channels to size and add holes and markings. As it needs zero setup time and cuts on all four sides, it’s effective even for one-offs.

Hydmech V-25 APC vertical band saw – A heavy-duty vertical saw, the V-25APC efficiently cuts both solid and structural material and is extremely versatile for many different types of sawing applications. Featuring a large 30″H x 25″W capacity, 10 HP motor, and 1 1/2″ blade, the V-25APC is a reliable choice for all your automated vertical metal cutting applications.

Bend-Tech Dragon A400 – The Dragon A400 CNC tube and pipe plasma cutter easily marks and engraves on tube and pipe to make CAD/CAM designs a reality. Ability to fabricate any design with holes and end cuts and marks all bending locations, rotations, and degrees on the tube. It is a massive time-saving tool for tube and pipe processing.

DB800 Dustless Blasting Pot – Cleaning structural metal fabrications for welding and coating is no longer a dirty, dusty job. This helps prevent weld cracking, improves coating adhesion, and makes for a better working environment, too.

Ermak Falcon 2600-100 Press Brake – This press brake is a CNC-controlled machine that bends sheet metal into pre-programmed shapes and has several features to increase productivity and reduce costs, including: User-friendly CNC controller, Low-cost hydraulic maintenance, IRIS Plus laser angle measurement and correction, and Motorized crowning system.

Powder curing oven – If they’re not made from stainless steel, fabrications need protection against corrosion, and powder coating is an excellent way to achieve that. Our large walk-in oven provides an even, consistent cure for the parts being coated.

Ask About Our Steel Fabrication Capabilities

We can design and fabricate large steel structures for clients in the Mid-Atlantic region including Maryland, Virginia, Delaware, West Virginia, Kentucky, Tennessee, Pennsylvania, Michigan, Wisconsin, and Illinois. Regrettably, size and weight make it cost prohibitive to ship further afield.

Examples of what we can produce include:

If you’re within reach of our facility in Oakwood, VA and you need fabrication work that’s durable yet accurate, we can help.

We have streamlined our steel fabrication process to make it as quick and easy on you as possible. For simple projects, our turnaround time is typically just 1-2 weeks. For larger and/or highly specialized projects, our turnaround time is typically 6-10 weeks.

You request a quote for your fabrication project

We provide a quote and drawing

You submit a purchase order

We fabricate your product to your requested specifications

We ship you your project

With over four decades of experience primarily building high-quality conveyor systems for industries like mining, quarrying, ports, and power generation, we have developed extensive steel fabrication capabilities. Our 125,000-square-foot manufacturing facility and skilled workforce set us apart, allowing us to take on large, complex projects at competitive prices. Let our expertise and commitment to quality drive the success of your next fabrication project. Call us at 877.910.0034 or use the link below to discuss your custom steel fabrication needs and discover how we can deliver exceptional results on time and within budget.

Conveyor systems are the lifeline of aggregate operations, keeping crushed stone, sand, and gravel moving efficiently through processing plants, storage yards, and onto transportation vehicles. However, the demanding nature of read more »

Gravel may seem simple at first glance, but in reality, its size, weight, and abrasiveness make it one of the most demanding materials to move. In mining and construction environments, read more »

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »