West River Conveyors will design, build, and install a customized radial stacker conveyor system for your material moving operations.

Our high-quality and durable conveyor systems will increase productivity, reduce environmental concerns, and improve your bottom line.

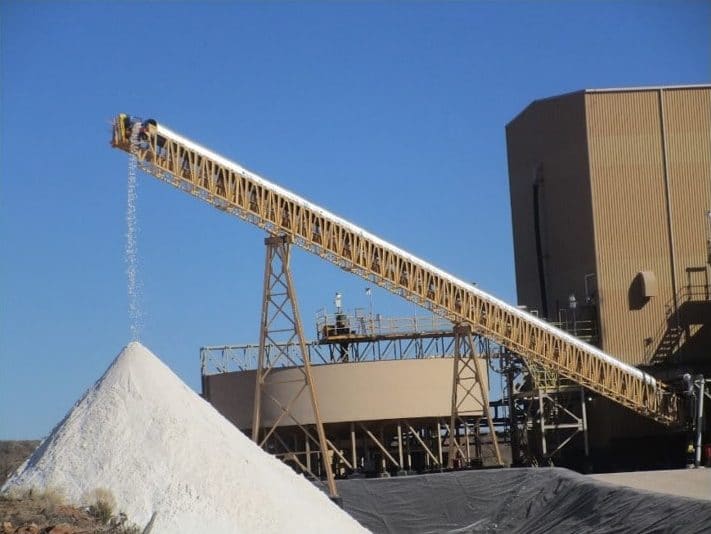

A radial stacker is a conveyor built into an inclined rigid truss that rests on wheels. This configuration allows it to rotate freely as it deposits material onto a pile at a rate of up to 1,200 tons of material per hour. Radial stackers are more efficient than wheel loaders or screw conveyors and create less dust and product damage.

Stacker conveyors are ideal for stockpiling many different types of quarry mining, heavy construction, bulk material handling and remediation applications, such as:

The radial stacker raises the material at a grade of up to 20° or more and then discharges it onto the top of the stockpile. Steeper inclines are possible but, depending on material properties, may require a specific conveyor belt design.

The intelligent design solves one of the most common stockpiling challenges. As aggregate stacks get higher, they get more difficult to work with, thereby hindering production and profitability. Radial stacker conveyors fix this problem.

Rotating radially in an arc will allow you to stockpile a significant amount of material in high and wide piles. This will prevent you from having to continuously move the equipment once the pile reaches a certain height.

An operator can start a new stack by simply repositioning the conveyor head once the stockpile reaches a preferred height. In other words, no more time-consuming halts to relocate equipment.

You’ll realize greater uptime, production, and profits with a radially moving stacker. Other benefits include:

The radial stacker conveyor lets you create stockpiles over a broad, sweeping arc. A radial stacker offers better storage density and a wider range of optional features than a standard stacker conveyor.

There are two types of radial stackers extensively used in the industry:

Consider a telescoping radial stacker for even greater storage density and space utilization. A telescoping stacker’s discharge point (the head) can extend further from the loading point. This expands the stockpile and reduces the material segregation that occurs when stacking a conical pile.

A portable radial stacker is suitable for producers who spend time on the road, travel from site to site, or move within a mine or quarry. A portable stacker’s tires swivel, switching position to allow for inline travel or radial action. A portable radial stacker may include fixed-width or telescoping axle configurations, depending on the application and size of the stacker.

West River Conveyors will design and build a radial stacker conveyor to fulfill your material handling requirements.

Components central to all such conveyors include:

Optional radial stacker system components include:

The truss and related components of a stacker should be made from materials that ensure the lasting durability of the equipment.

West River Conveyors can build your stacker conveyor from:

At West River Conveyors, we pay specific attention to minimizing the effects of dust on moving parts. We select drives, belts, and other components to suit the conveyed material. Troughed belts are ideal for maximum load capacity. Belt speed, width, and stacker length are configured to meet each application.

With over four decades of experience, our team appreciates the challenges of conveying abrasive, dusty, heavy, and even potentially hazardous materials. We provide custom conveyor systems and parts to mines, quarries, and many other bulk material operations.

Located in Oakwood, Virginia, we’ve earned the respect of producers throughout North America. Our team is dependable and knowledgeable. See for yourself, by reaching out to discuss your conveying needs!

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »

At West River Conveyors, we believe in being upfront with our customers, especially when changes in the global economy may impact your business. As a family-owned company proudly manufacturing conveyor read more »

A reliable conveyor system is essential for efficient mining operations. However, even the most well-maintained conveyor systems degrade over time, leading to inefficiencies, downtime, and higher operational costs. Knowing when read more »