Choosing the right surface conveyor belt helps to avoid unplanned downtime and costly repairs. Heavy, sharp-edged, and abrasive materials can cause belt rips and tears, bringing operations to a grinding halt.

West River Conveyors carries a wide selection of hot, plied, and steel cord outdoor conveyor belts from reputable manufacturers. Our engineers will match the belt type to the material you’re moving to ensure a long lifespan and trouble-free performance.

Our outdoor belts bring a wealth of benefits to your material-moving operations. With features tailored to accommodate a range of needs, our belts stand out for their:

Manufacturers construct surface conveyor belts from two layers of durable cover sandwiching the inner construction. The upper layer of the cover needs to stand up to wear imparted by the transported material. The inner part of the belt provides strength and extension resistance. The bottom layer requires strength and flexibility to run over supporting rollers and pulleys.

Covers are either rubber or a shock-absorbing Resorcinol Formaldehyde Latex (RFL)-dipped textile material. A coating of RFL helps textile materials form a durable bond with rubber.

Select from one of three breaker options that include steel, fabric, or aramid (a Kevlar-type material) for enhanced impact resistance and rip protection. Special covers are available for transporting hot materials.

Belt inner construction consists of a multi-ply textile or rubber with longitudinal steel cords.

Consider the following when making your selection:

Engineers specifically design plied belts for quarries, mines, power plants, and other operations transporting heavy and abrasive materials. These belts consist of rubber covers over two to four or more textile plies. The manufacturer dips the textiles in RFL before assembly to ensure a strong bond to the rubber.

Plied belt benefits include:

Composed of steel cables at a constant pitch across the belt, they’re ideal for narrow-width applications. The zinc-plated cables for corrosion protection feature an open structure that facilitates excellent bonding with the rubber. For additional rip protection, consider adding a textile or steel breaker.

Steel cord belt benefits include:

These belts have a multi-ply construction and a rubber cover. Intended for transporting hot materials, they are fire-resistant and offer good abrasion resistance. Remember that operations subject to MSHA Part 14 regulations should not use these belts.

Hot belt benefits include:

West River Conveyors offers multiple types of surface conveyor belts designed to increase performance and reduce the risk of unplanned downtime. We’ll work closely to understand your unique challenges and recommend the ideal belt for trouble-free and long-lasting performance.

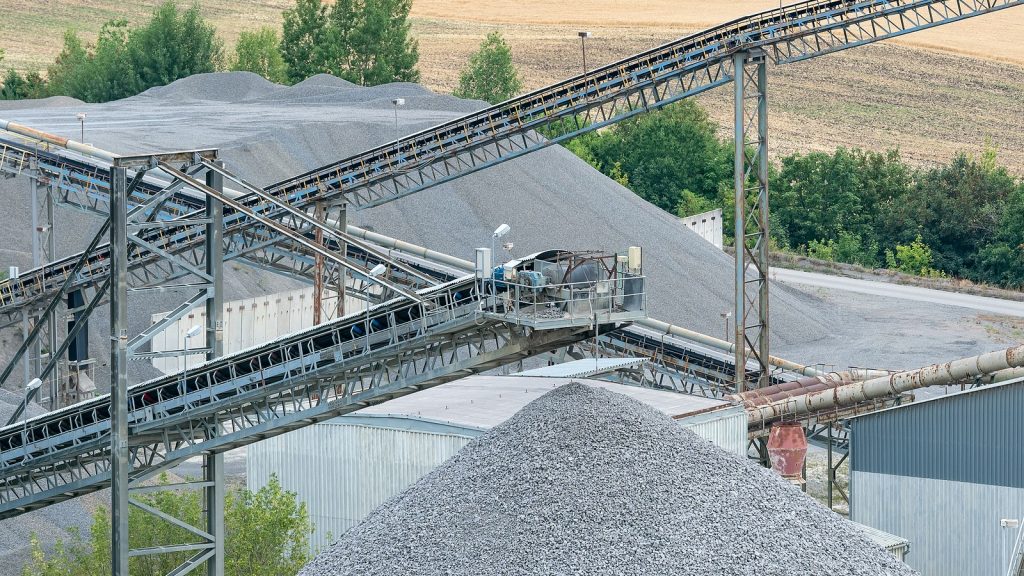

Conveyor systems are the lifeline of aggregate operations, keeping crushed stone, sand, and gravel moving efficiently through processing plants, storage yards, and onto transportation vehicles. However, the demanding nature of read more »

Gravel may seem simple at first glance, but in reality, its size, weight, and abrasiveness make it one of the most demanding materials to move. In mining and construction environments, read more »

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »