A heavy-duty belt cleaning system is essential for conveyor systems operating in harsh mining conditions. Also known as a belt scraper, its primary function is to remove bulk material from conveyor belts.

Belt scrapers help to prevent buildup and ensure efficient operation. They reduce the risk of belt damage, premature wear, and worker accidents by eliminating potential hazards associated with material accumulation.

West River Conveyors carries high-quality primary and secondary belt scrapers. They’re designed to work with various belt sizes, speeds, and industries. Contact us today for a quote.

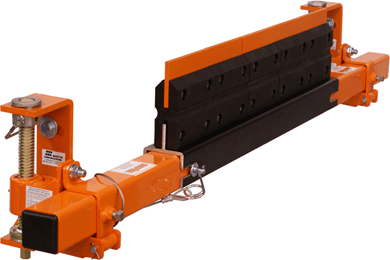

Primary conveyor belt cleaners are essential for improving efficiency and durability in conveyor systems. The primary scraper has a more aggressive and robust blade to handle additional materials.

The primary scraper is strategically positioned at the discharge end of the conveyor. This allows it to act as the first line of defense against carryback. It actively cleans the conveyor immediately after material transport.

Secondary conveyor belt cleaners have lighter and less aggressive blades. They’re positioned further down the conveyor line to remove any remaining carryback effectively. Their simple yet efficient design allows for seamless integration into existing conveyor systems.

West River Conveyors is proud to offer a wide selection of high-quality primary and secondary belt scrapers from Martin Engineering. These scrapers ensure thorough cleaning of conveyor belts, maximizing efficiency and minimizing maintenance requirements. We offer several models tailored to meet the specific needs of your conveyor system.

Primary scrapers can accommodate belts up to 120 inches wide and operate at speeds up to 2,000 feet per minute. They’re manufactured out of premium-grade steel and high-performance urethane materials to withstand the rigors of continuous operation in demanding mining environments. Replacing and maintaining blades is also quick and straightforward, thanks to their user-friendly design.

Secondary belt scrapers are installed where the belt leaves the discharge pulley. Their purpose is to remove any material the primary cleaner missed. They are positioned close to the primary cleaner, so discharged material falls back into the main flow. Additional secondary cleaners provide final belt cleaning before the return idlers.

Belt scrapers are essential for keeping conveyor belts clean and optimizing material flow. Proper selection is crucial because the scraper must be tailored to the specific needs of the conveyor system. This includes the type of material transported, the environment in which the conveyor operates, and the characteristics of the belt.

The following specs apply to both primary and secondary scrapers:

Blade Type—The primary scraper is positioned on the head pulley, removing the bulk of material from the belt. The secondary scraper is installed after the primary scraper to clean the belt further and improve cleaning efficiency.

Mounting—Fixed mounting scrapers are stationary and mounted rigidly to the conveyor structure. Floating mounting scrapers are mounted on a flexible arm or tensioner. This allows it to follow the contours of the conveyor belt.

Adjustability—Some scrapers have tension adjustment mechanisms to control the pressure applied to the belt. The blade position adjustment allows for fine-tuning the scraper’s contact with the belt.

Wear Life and Durability—The scraper material should resist wear and abrasion to ensure a longer service life. It should also resist corrosion if the conveyor operates in a corrosive environment.

Temperature Range—The scraper should be suitable for the temperature range of the conveyed material and the operating environment.

Cleaning Efficiency—The design should ensure effective cleaning without causing damage to the conveyor belt.

Compatibility—Ensure the scraper is compatible with the specific conveyor belt and system type.

Installation and Maintenance—Consider ease of installation and maintenance to minimize downtime.

Regulatory Compliance—Ensure the scraper complies with relevant safety and environmental regulations.

Customization—Some applications may require custom-designed scrapers. Check if the manufacturer provides customization options.

Documentation—Product documentation should include installation guidelines, maintenance instructions, and other relevant information.

After the main conveying process, the scrapers remove the remaining material on a belt. These scrapers are typically made of highly durable materials to withstand harsh operating conditions. They are installed at strategic points along the conveyor to prevent the material accumulation of material reduced belt damage.

Primary Belt Scrapers—The initial line of defense against carryback is primary scrapers installed at the head pulley, where the belt is most likely to retain material. They aggressively scrape off the bulk of the material adhering to the belt. This helps ensure carryback removal before the belt returns to the loading zone.

Secondary Belt Scrapers—We typically install downstream scrapers after the primary scraper to provide additional cleaning. These scrapers remove any material the primary one misses. Using multiple scrapers works well for sticky, abrasive materials or high-speed conveyors.

Self-Adjusting Mechanisms—Many modern belt scrapers have self-adjusting mechanisms that automatically adjust to changes in belt tension, wear, and other variables. This ensures the scraper maintains optimal contact with the belt, providing consistent cleaning performance.

Application-Specific Design—The need for primary and secondary scrapers can vary depending on the specific application. For instance, they’re both often used in mining and aggregate operations to handle heavy loads and abrasive materials. Properly positioned primary scrapers can prevent cross-contamination in sanitary food processing industries.

Customized Solutions—Conveyor system designers and operators can tailor the use of primary and secondary scrapers based on the specific needs of their operation. For example, a standalone primary scraper works well if the conveyor system is relatively short or the conveyed material does not present a significant carryback risk. On the other hand, long systems or those with sticky materials may need both primary and secondary scrapers to maximize cleanliness and efficiency.

Installing primary and secondary belt scrapers requires considering the material’s nature, conveyor length, and the operating environment. While using both scraper types frequently provides comprehensive cleaning, specific applications may call for using one over the other based on their particular requirements.

It’s essential to carefully consider your specific use case when choosing a belt scraper. They’re highly effective in industries like mining and cement, where large amounts of material are transported. The right type and size of the scraper depends on the material you’re moving, the conveyor belt width, and the workplace environmental conditions.

Abrasive materials necessitate a durable surface scraper to withstand wear and tear. Sticky materials may require a specially designed blade. Additionally, scraper materials must be rugged enough to resist extreme temperatures or chemical exposure.

Other factors to consider include:

Material Compatibility—Choose a scraper that matches the nature of the material, whether it’s abrasive, sticky, or standard.

Belt Width Compatibility—Ensure the scraper is appropriate for your conveyor belt’s width for efficient cleaning.

Environmental Resilience—Select materials that can endure the specific environmental challenges of your workplace, like high temperatures or corrosive elements.

Blade Design and Durability—Opt for a blade shape and material that offers both effectiveness in cleaning and longevity.

Maintenance and Cost—Consider how easy it is to maintain and replace parts of the scraper. Balance the initial purchase price with long-term maintenance costs.

Manufacturer Reputation and Compliance—Select a scraper from a reputable manufacturer to guarantee quality and reliability. Ensure it meets industry standards and regulations.

West River Conveyors is a leader in mining conveyor equipment, including custom remote discharges, conveyor structures, fluid couplings, and more. We offer excellent pricing on primary and secondary scrapers and cleaners. Contact us below to learn more and get a quote.

A: Primary scrapers are for initial cleaning. Secondary scrapers provide additional belt cleaning in a different location on the conveyor.

A: The size of it should match and cover the width of the conveyor belt for maximum cleaning.

A: It usually depends on the environment; some will wear out a scraper faster than others. You should replace blades when they become ineffective.

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »

At West River Conveyors, we believe in being upfront with our customers, especially when changes in the global economy may impact your business. As a family-owned company proudly manufacturing conveyor read more »

A reliable conveyor system is essential for efficient mining operations. However, even the most well-maintained conveyor systems degrade over time, leading to inefficiencies, downtime, and higher operational costs. Knowing when read more »