West River Conveyors manufactures purpose-built tail sections to withstand the harshest mining conditions. Our highly customized units accommodate various length, horsepower, height, and belt width requirements.

The proven heavy-duty structural design and robust components ensure long-lasting performance. This innovative engineering maximizes uptime and minimizes maintenance costs, even in the most demanding applications.

Let the experts at West River Conveyors engineer and build a custom conveyor tail section for your application.

Tail sections are an essential piece of any conveyor system. Their design and build quality can significantly affect a mining operation’s overall efficiency and performance. Benefits include:

At West River Conveyors, we engineer and build several types of conveyor tail sections designed to match each customer’s unique application. Choose from a wide range of belt widths, including 48”, 60”, and 72”.

We offer impact bar and glide bar options made out of UHMWPE, an ultra-high molecular weight polyethylene. This specialized plastic absorbs impact and reduces friction.

Learn more about the different types we offer below.

Tail Section

There are three different tail section bar options: impact bar, impact bed, and glide bar. Customer preference typically determines the choice of the bar—beds are longer, whereas the bars are shorter and in more sections. They essentially function the same.

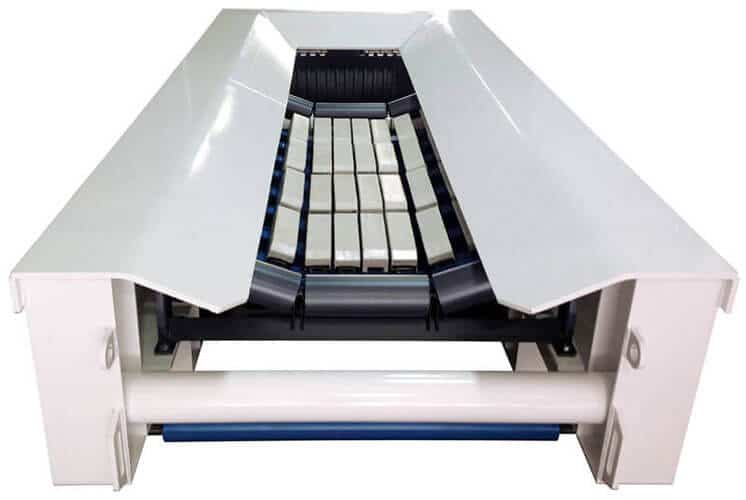

Tail Section with Guarding

Robust guarding is critical for the tail section of mining conveyors to promote safety and performance. Heavy-duty mesh or perforated steel guards encase the key danger zones along the tail to prevent access to moving parts.

Strategically placed access doors and hatches allow inspection and maintenance while minimizing exposure. The guarding contains material discharge and spillage to optimize flow control.

By preventing personnel access and buildup underneath, the tailored guarding reduces safety risks and maintenance issues. The rugged guarding withstands the tough conditions and hazards of mining applications.

When engineering a custom unit, our engineers consider key application factors, such as: conveyor type, load details, operating environment, and budget. We account for the unique needs of belt, roller, or screw conveyors. The size and weight of your loads inform critical design choices to handle expected throughput. Selecting intelligent materials and features allows us to build sections that withstand corrosion or other hazards.

By working within your budget, we determine possibilities for specialized components while keeping costs minimized. Analyzing these application-specific factors enables us to tailor the perfect tail section that maximizes performance and longevity for your constraints. Our customized approach delivers solutions engineered for your exact specifications and operational needs.

A tail section of a conveyor is the opposite end of the head drive – the turn around/loading point. Every conveyor system has a tail section or transfer chute at the end of one belt line. This terminal area contains a structural framework to absorb impact from discharged material.

Key components include:

Belt cleaning mechanisms in the tail section remove residual material on the return side to prevent carryback and spillage. Overall, they provide a durable, controlled transition point to handle high-impact loading and keep your system running efficiently.

Proper integration with the rest of the conveyor system is crucial for optimal performance. Factors like discharge height, belt alignment, and chute design must match seamlessly between the conveyor and tail section.

Dust control and spillage containment should extend back onto the conveyor frame. Belt cleaning and tracking components must align with the conveyor belt.

We help customize all aspects to ensure proper integration with the conveyor length, width, capacity, and other parameters.

With over 1,500 custom units built to date, West River Conveyors has the expertise to deliver high-performing and durable solutions. We can also provide quick turnaround times to meet your deadlines. Request a quote below to learn why our proven design produces superior results.

Conveyor systems are the lifeline of aggregate operations, keeping crushed stone, sand, and gravel moving efficiently through processing plants, storage yards, and onto transportation vehicles. However, the demanding nature of read more »

Gravel may seem simple at first glance, but in reality, its size, weight, and abrasiveness make it one of the most demanding materials to move. In mining and construction environments, read more »

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »