Remote discharges are designed to seamlessly transfer materials from one conveyor belt to another.

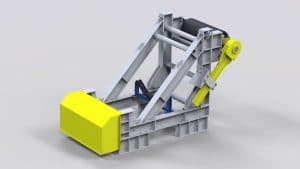

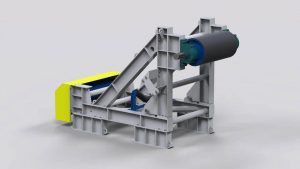

West River Conveyors has built many types of remote discharges, especially those with an A-frame design. Our heavy-duty structural steel designs can accommodate many customized engineered options, including floor or roof mounts, provisions for mounting belt cleaners and pulleys with an adjustable or fixed boom.

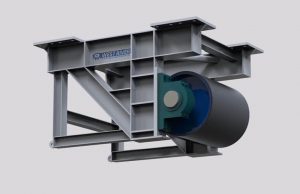

West River’s remote discharge design typically consists of a pulley-and-frame assembly that’s separated from the drive unit.

Remote discharges are located at the end of a conveyor.

Materials can exit the conveyor through one or more discharge chutes , and may employ muliple chutes utilizing slide gates to distribute the material to various downstream processes.

These factors largely depend on the material characteristics the conveyor is transporting, particularly the density of the ore.

Weight, sharpness, and abrasiveness are also important properties to consider when designing a discharge.

Individual Mine requirements

Equipment will be customized based on the following:

Contact us to learn more about our Custom Engineered Remote Discharge equipment options.

West River Conveyors is a leader in mining conveyor equipment including, custom remote discharges, conveyor structures, fluid couplings, and more.

We offer excellent pricing on custom-engineered remote discharges, and in some cases can extend competitive deals if you’re adding components to a package.

Conveyor systems are the lifeline of aggregate operations, keeping crushed stone, sand, and gravel moving efficiently through processing plants, storage yards, and onto transportation vehicles. However, the demanding nature of read more »

Gravel may seem simple at first glance, but in reality, its size, weight, and abrasiveness make it one of the most demanding materials to move. In mining and construction environments, read more »

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »