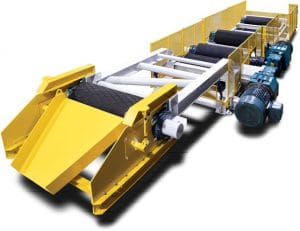

An Alignment-Free Drive refers to the power base components — reducer, fluid coupling and motor — properly constructed to eliminate shaft misalignment. With an Alignment-Free Drive, there are two critical elements, input and output, where the need to align is completely eradicated, making it a great choice for those interested in long-term cost savings and efficiency.

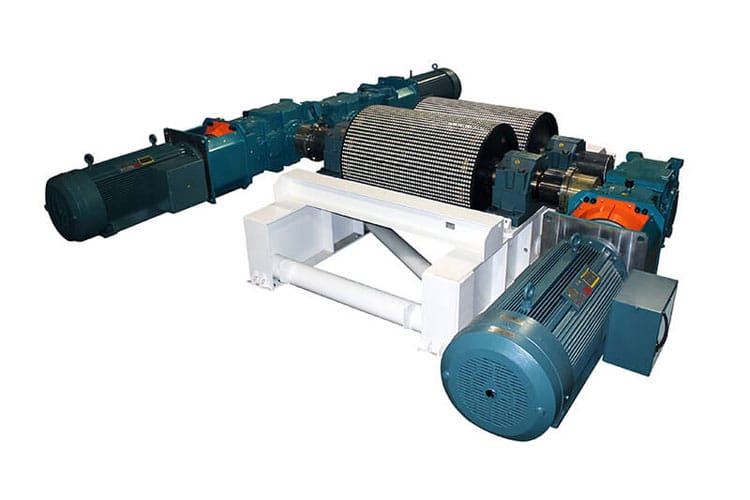

The Triple 500HP Alignment-Free VFD Drive (60″ belt width) pictured at right was constructed with heavy-duty structural steel and built to exact customer specification — with the addition of ceramic lagging to the pulleys and an option. Equipped with three 500HP motor bases, it produces a total of 1500HP. The Triple 500HP drive is controlled by a sophisticated Variable Frequency Drive starter to increase speed, maneuverability, and responsiveness. By using a VFD starter, longevity of the drive is attained in addition to energy and cost savings.

West River’s Alignment-Free Drives are offered in any desired belt width and horsepower/voltage required.

In today’s competitive mining environment, operational efficiency isn’t just a goal—it’s a necessity. From maximizing material throughput to minimizing downtime, mining companies are under pressure to improve productivity across the read more »

At West River Conveyors, we believe in being upfront with our customers, especially when changes in the global economy may impact your business. As a family-owned company proudly manufacturing conveyor read more »

A reliable conveyor system is essential for efficient mining operations. However, even the most well-maintained conveyor systems degrade over time, leading to inefficiencies, downtime, and higher operational costs. Knowing when read more »