High-precision scans eliminate manual measuring errors and provide a reliable foundation for retrofit and upgrade designs.

Scans reveal interference points, misalignment, and wear, so issues can be addressed before engineering begins.

Detailed 3D models help you visualize equipment layouts and identify ideal locations for access doors, clean-out zones, and other maintenance tools.

West River Conveyors conducts comprehensive onsite assessments using advanced scanning technology to capture millimeter-accurate dimensional data of your existing conveyor systems. This precise information eliminates the need for manual measurements and provides a permanent 3D record that integrates seamlessly with our design tools for retrofit modeling and project planning.

Following the scan, our team performs a value assessment to identify cost-effective solutions aligned with your operational goals, supported by clear expectations and measurable success metrics. Each assessment includes detailed scopes of work and formal system-level quotations, with the full onsite process (meetings, inspections, and measurements) typically completed in just one to two days.

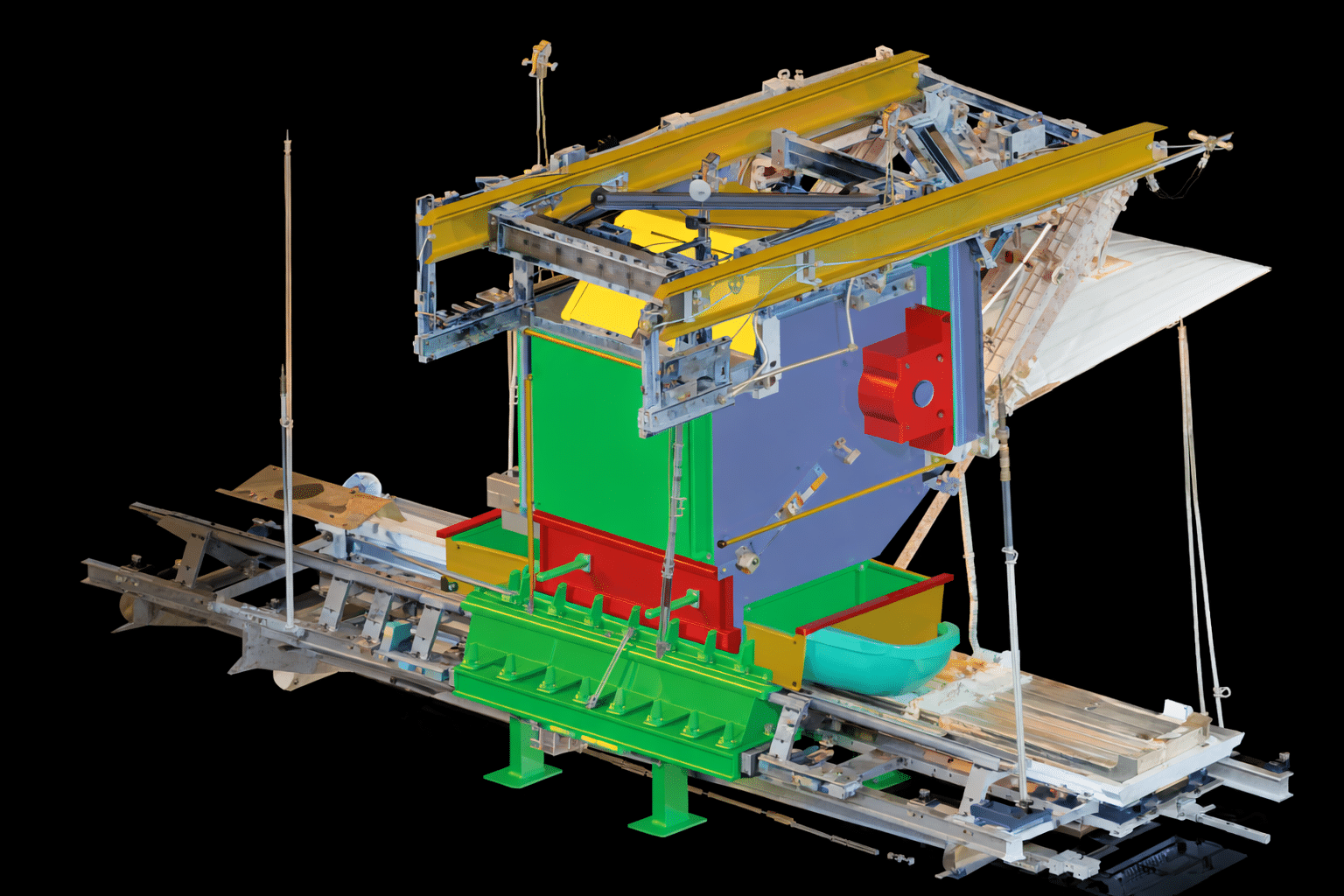

WRC’s high-precision 3D laser scanning technology captures as-built environments by generating dense point clouds of your existing conveyor systems and surrounding structures. These scans record the exact layout of chutes, belts, hoppers, and supports, enabling highly accurate retrofit and upgrade planning.

Once captured, the scan data can be converted into CAD models and used with Discrete Element Modeling (DEM) software, giving engineers a precise digital foundation for designing replacements, improving flow, and solving material-handling challenges.

When you choose West River Conveyors, you’re partnering with a team that pairs advanced scanning technology with decades of conveyor engineering expertise. Our specialists translate precise scan data into practical, cost-effective design solutions that enhance safety, performance, and reliability.

From initial assessment through final engineering, we work collaboratively, communicate clearly, and deliver recommendations grounded in real-world mining and material-handling experience, giving you confidence that every decision is informed, accurate, and built to last.

Cost-effective solutions for hauling aggregates like sand and gravel over long distances.

LEARN MORE

Improve mining operations with custom conveyors that are tested for safety and reliability.

LEARN MORE

An online inventory stocked with gearboxes, fluid couplings and other parts ready to be shipped.

LEARN MORE

Avoid unplanned downtime and injuries that can arise from worn out conveyor belts.

LEARN MOREMaintaining proper belt tension is essential for efficient, safe, and reliable conveyor operation. In mining applications where conveyors must handle heavy loads over long distances, a well-designed tensioning system—commonly referred read more »

As 2025 comes to a close, mining and bulk-materials handling operations are navigating evolving market conditions, cost pressures, and shifting demand. These changes are driving new investments while also creating read more »

When it comes to designing or troubleshooting a mining conveyor system, one of the most common questions engineers ask is: How much material can my conveyor actually handle? The answer read more »