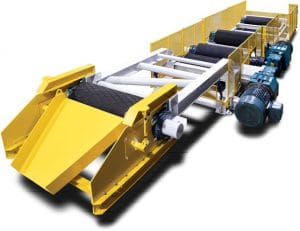

An Alignment-Free Drive refers to the power base components — reducer, fluid coupling and motor — properly constructed to eliminate shaft misalignment. With an Alignment-Free Drive, there are two critical elements, input and output, where the need to align is completely eradicated, making it a great choice for those interested in long-term cost savings and efficiency.

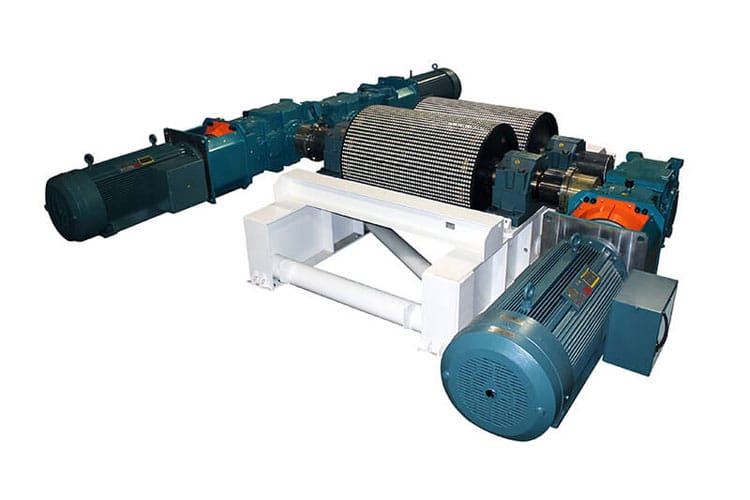

The Triple 500HP Alignment-Free VFD Drive (60″ belt width) pictured at right was constructed with heavy-duty structural steel and built to exact customer specification — with the addition of ceramic lagging to the pulleys and an option. Equipped with three 500HP motor bases, it produces a total of 1500HP. The Triple 500HP drive is controlled by a sophisticated Variable Frequency Drive starter to increase speed, maneuverability, and responsiveness. By using a VFD starter, longevity of the drive is attained in addition to energy and cost savings.

West River’s Alignment-Free Drives are offered in any desired belt width and horsepower/voltage required.

Cost-effective solutions for hauling aggregates like sand and gravel over long distances.

LEARN MORE

Improve mining operations with custom conveyors that are tested for safety and reliability.

LEARN MORE

An online inventory stocked with gearboxes, fluid couplings and other parts ready to be shipped.

LEARN MORE

Avoid unplanned downtime and injuries that can arise from worn out conveyor belts.

LEARN MOREMaintaining proper belt tension is essential for efficient, safe, and reliable conveyor operation. In mining applications where conveyors must handle heavy loads over long distances, a well-designed tensioning system—commonly referred read more »

As 2025 comes to a close, mining and bulk-materials handling operations are navigating evolving market conditions, cost pressures, and shifting demand. These changes are driving new investments while also creating read more »

When it comes to designing or troubleshooting a mining conveyor system, one of the most common questions engineers ask is: How much material can my conveyor actually handle? The answer read more »